As winter gives way to spring in Wilmington, DE, the immediate focus for many commercial and industrial facilities shifts from heating to cooling. However, before adjusting your thermostat or firing up the air conditioning, it is crucial to evaluate your HVAC system for any hidden wear or damage that occurred during the colder months. Winter can be especially tough on HVAC systems, particularly in regions like Delaware where freezing temperatures, snow, and ice are part of the seasonal norm.

Commercial HVAC maintenance after winter is not just a good practice. It is a necessary investment in operational efficiency and system longevity. The intense workload that heating systems bear during the coldest months often leaves behind a trail of subtle mechanical stress, refrigerant imbalance, or clogged components. Ignoring these issues could mean operational failures just when the first wave of summer humidity rolls in. If your business depends on reliable indoor climate control, proactive inspections and repairs now can prevent costly disruptions later.

Why Heat Exchanger Inspection is Essential Post-Winter

Heat exchangers play a pivotal role in the efficiency and safety of your heating systems. Over the winter, these components endure constant cycles of heating and cooling. This thermal expansion and contraction can cause small cracks to form in the metal, which may not be immediately obvious. Even a minor crack in a heat exchanger can lead to serious safety risks, including carbon monoxide leaks.

For commercial and industrial heating and cooling repair teams in Delaware, post-winter heat exchanger inspection is one of the most critical tasks. It allows for early detection of deterioration that could compromise system integrity. In older systems, corrosion from condensation can also lead to weakened exchanger surfaces. If neglected, this kind of damage might remain invisible until it escalates into a full system shutdown or a health hazard for building occupants.

Using specialized tools such as combustion analyzers and borescopes, HVAC professionals can assess the condition of your heat exchanger without disassembling the entire system. Early identification of issues at this stage avoids expensive downtime and keeps your building’s air quality and safety standards intact.

The Hidden Toll of Ice on Condenser Coils

Another frequently overlooked consequence of winter weather is the impact on your outdoor condenser coils. These coils are vital in the heat transfer process, and when they become clogged with debris or develop damage due to ice buildup, their efficiency plummets. In colder months, ice can accumulate around the coil area, especially when snowdrifts pile up around outdoor units or drainage is inadequate. As the ice melts and refreezes, it can warp coil fins or even puncture the tubing.

Condenser coil cleaning is essential during seasonal HVAC maintenance. Not only does this improve heat exchange efficiency, but it also reduces the risk of the system overworking during warmer months. When condenser coils are dirty or damaged, the system must work harder to achieve the desired cooling effect. This leads to increased energy consumption and a higher risk of premature compressor failure.

In the commercial HVAC maintenance calendar for Wilmington, DE, condenser coil inspection and cleaning should be scheduled in late winter or early spring. A thorough cleaning using proper chemical agents and fin combs can restore efficiency and ensure your system is ready for the cooling demands of summer.

Refrigerant Leak Detection: Stop the Loss Before It Starts

Refrigerant is the lifeblood of any cooling system. During winter, however, fluctuating temperatures and pressure changes can cause seals to contract, connections to loosen, and hairline cracks to form in the refrigerant lines. These small issues often go unnoticed until refrigerant levels drop low enough to affect performance.

In a commercial setting, refrigerant leaks can have a cascading effect on operational efficiency. They not only reduce the system’s ability to cool properly but also lead to higher energy costs and increased strain on the compressor. In extreme cases, the compressor may overheat and fail altogether, requiring expensive emergency repairs.

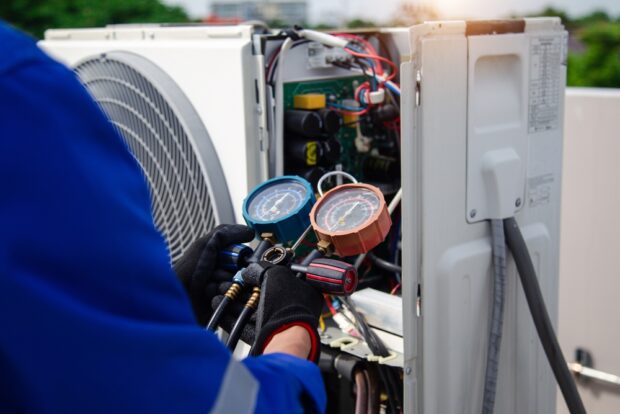

Refrigerant leak detection should be a non-negotiable part of your HVAC winter damage assessment. Using tools such as electronic leak detectors, UV dye kits, and pressure gauges, certified technicians can locate and resolve leaks before they cause broader system issues. In Delaware’s tightly regulated commercial environment, addressing leaks early also ensures compliance with environmental and safety standards related to refrigerant handling and disposal.

Preparing for Humidity: Why Spring Maintenance Matters

The end of winter is not just about turning off the heat. It is about preparing your HVAC system to transition smoothly into a very different mode of operation. Humidity levels in Delaware can spike rapidly in late spring and early summer. If your system is not ready to handle the added stress of moisture removal, indoor air quality and occupant comfort can suffer.

Moisture control relies heavily on a well-functioning air conditioning system. A neglected system may struggle with dehumidification, leading to issues like mold growth, musty odors, and even structural damage to sensitive building materials. That is why thorough commercial HVAC maintenance in early spring should include a full system calibration, drain line inspection, and filter replacements.

If winter caused any blockage in your condensate lines or compromised insulation around ductwork, humidity can start to accumulate in places it should not. A comprehensive HVAC winter damage assessment looks at all of these potential risks, ensuring that your system is optimized not just for temperature control but also for effective humidity management.

Conclusion: Turn the Page on Winter the Smart Way

The shift from winter to spring is a critical period for facility managers and property owners in Wilmington, DE. The hidden fatigue accumulated by your HVAC system during months of intensive heating can quietly evolve into expensive problems once the weather changes. From inspecting heat exchangers to conducting condenser coil cleaning and refrigerant leak detection, now is the time to reset your system for peak performance.

Industrial heating and cooling repair services in Delaware are best positioned to help you identify and mitigate these risks. Investing in professional, seasonal maintenance ensures that your HVAC system runs cleanly, safely, and efficiently. As the humidity approaches, a little foresight can go a long way in avoiding downtime and maintaining a healthy indoor environment for your tenants, employees, or customers.

Don’t let winter’s hidden damage catch you off guard. With the right commercial HVAC maintenance strategy, you can catch system fatigue before it snowballs into a costly summer emergency.

Need Commercial HVAC Repair in Wilmington, DE?

Since 1984, Commercial Equipment Service Inc. has been providing service and sales of commercial/restaurant cooling, refrigeration and heating equipment to Wilmington, Delaware and the surrounding area. We are a locally owned business with over 42 years of experience. Our friendly staff prides itself on our professional attitude and service. Commercial Equipment Service Inc. is a 24/7 on-call service for your appliance needs! We install and repair all refrigeration and cooking equipment, heating and air conditioning, emergency generator sales, kitchen exhaust systems, beverage systems and so much more. Contact us today to learn more about what we can do for you!